We utilize the expertise of our factory trained technicians as well as a state of the art service department to perform computerized static and dynamic testing of servo valves.

We believe in the Quality of our servo valve repair services so much, that we provide a 12 Month In-Service Warranty on the entire valve. To read more about our Servo Valve Repairs, please view our Brochure.

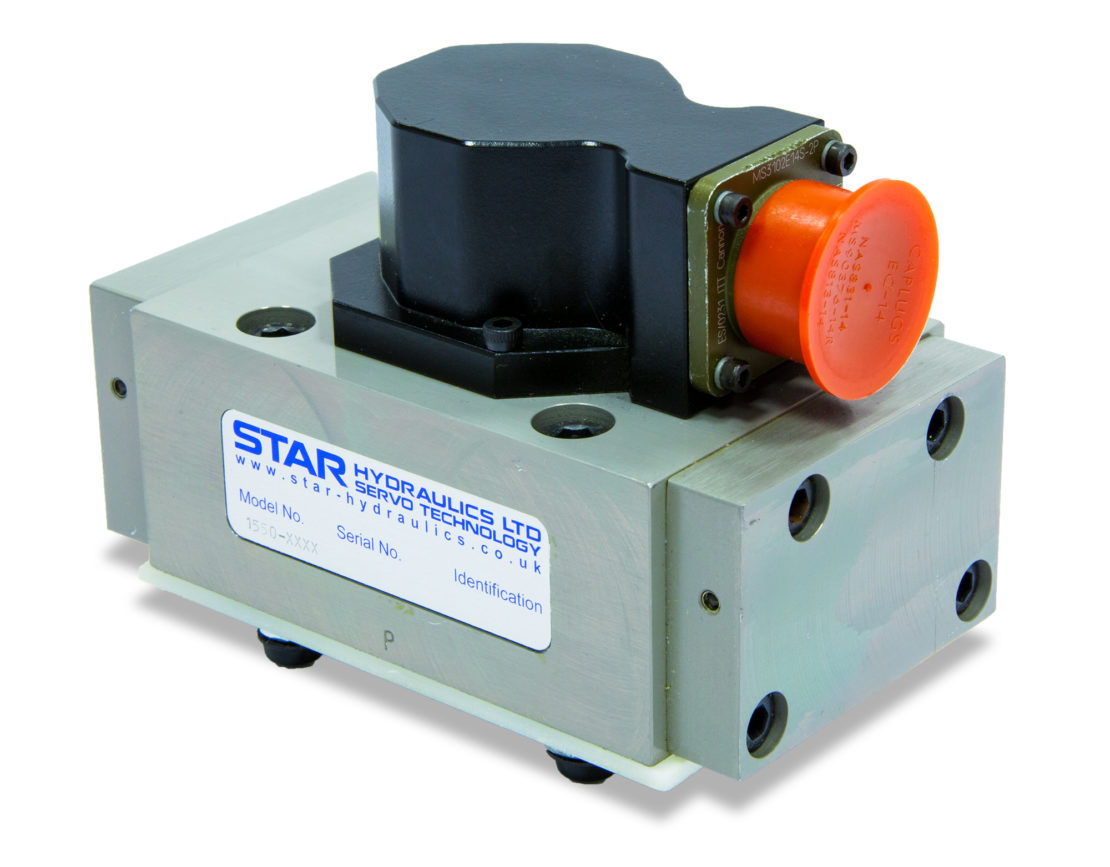

Common Manufactures Supported include: Rexroth Bosch, Moog, Parker, Star Hydraulics, Schenk Pegasus, Vickers and more.

Repair Process

- Valve is pressurized on dedicated test stands and command signal is applied. Valve response and internal leakages are noted.

- Valve is completely disassembled and inspected for wear or damage. Any findings during this process are noted on our “Failure Analysis Reports” which are supplied free of charge to our customers.

- All valve components are ultrasonically cleaned.

- All failed parts are changed with new components.

- New Seals and Pilot filter are installed.

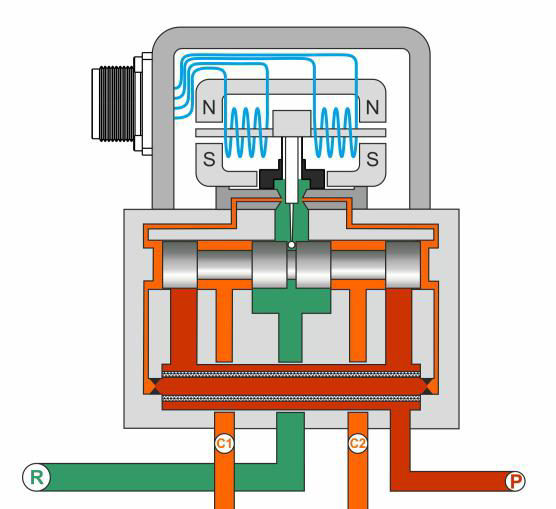

- First stage is calibrated on specialized test fixtures where nozzles pressures, magnetic gain, and gapping is verified and adjusted.

- Valve is Computer Tested under load and a Test Report is generated. A copy of this report is sent back to the customer with the repaired valve. (Command Signal, Flow Output, Feedback Signal, Pressure, and Internal Leakage are recorded.

In addition to servo valve repair, K+S Services offers a wide variety of industrial repair services including: hydraulic repair, hydraulic cylinder repair, hydraulic pump repair, welder repair, cnc repair and much more. Contact us today for more details.

Star Servo Valve Interchangeable and Comparison Chart

Servo Valve applications in various industries:

- Paper Mills: In paper mills, servo valves are used in calendaring lines. These calendaring lines consist of 2 rollers per machine and can have up to 9 servo valves on each roller. The paper is run through these highly polished rollers, and smoothes the paper by compression. Valves such as the Moog D656Z052, Star 650-0074, Dowty 4682-264-000 and Dowty 4682-263-000 are commonly used.

- Power Generation: Servo valves can be found in use in power generation plants. They are used to control the hydraulic actuator position for the inlet guide vanes. Moog G77K201, Moog EO77-655, Moog D634-501, Star 850-0002, Star 456-0010, Pegasus SLS 325, Dowty 469302490901, and the Rexroth 4WS2EM10-45-20B3T315K8DV-24 are some of the valves used.

- Railways: All countries have a railway system which requires specialized maintenance machinery. Originally the ballast which was 300mm deep, supported wooden sleepers and it was left to a manual maintenance team to keep the system running. With more concrete sleepers being used it became impossible to manually lift the sleepers to pack ballast underneath thus the need for specialist machinery.

Rlasser rail valves by Star and Moog are often used and Harsco rail valves used on tampers, stone blowers and welders by Star are commonly used. - Remote Operated Vehicles – ROV: For several years we have been repairing and supply servo valves to integrated subsea services who operate various remote operated vehicles. Valves that have been repaired and purchased include: New Star Valves 200-0016, Moog Miniature Valve 30-389A, Moog E050-031, Moog E777-006 and Dowty 4633-119-901.

- Saw Mills: Servo valves can be found throughout the wood industry. They are used to control speed and position in applications like saws, carriages, edge controls and optimizers.

- Wind Turbine: Wind turbines can be found either on land or offshore. The servo valves used in these applications control the blade pitch thus controlling the speed at which it moves.

- Earthquake Simulation: There are many companies who manufacture earthquake simulation equipment. They lower a plate onto the ground and produce vibrations through the plate. The common valve used is the Atlas 200H or 240H with either a Moog 760C928A or Star 590-1100 pilot valve.

Learn more about our Valve Division: