Certified Repair Process

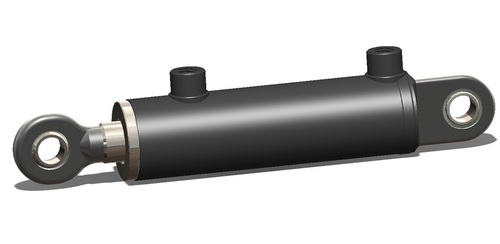

K+S’s hydraulic cylinder repair process is rooted in 40 years of expertise and commitment to precision and durability. Whether we’re asked to repair single- or double-acting cylinders, tie-rod or welded-rod cylinders, or any other kind, count on K+S to repair or rebuild to the highest industry standards.

Precision Diagnosis

Identifying cylinder wear, seal degradation, and misalignment issues.

Cylinder-Specific Disassembly

Careful dismantling, focusing on rods, seals, and piston heads.

Targeted Cleaning and Inspection

Special attention to rod straightness and seal integrity.

Cylinder Component Repair/Replacement

Utilizing high-quality parts specific to cylinder repair.

Pressure and Leak Testing

Ensuring cylinders withstand operational pressures leak-free.

Customized Cylinder Reconditioning

Tailored repairs for single, double-end, or telescopic cylinders.

Skilled Cylinder Repair Technicians

Expertise and decades of experience in hydraulic cylinder restoration.

ISO 9001 Certified Process

Guarantees consistent quality in hydraulic cylinder repairs.

Brands

We can repair a wide range of hydraulic cylinder brands, including Caterpillar, Parker, Rexroth, and more. Contact us to learn more about the brands we service.

Does My Hydraulic Cylinder Need Repair?

Your hydraulic cylinder may need professional repair if you notice:

- Visible leaks or seepage.

- Decreased force or slow movement.

- Unusual noises during operation.

- Visible wear on rods or seals.

For more information about hydraulic cylinder conditions and our repair services, contact a K+S expert today.