Our highly trained team of engineers, 12-month certified in service warranty, dependable systems testing and extensive parts inventory enable K+S to offer comprehensive industrial machine component repair services at the highest level.

Our industrial repair services range from repair of electronic components, PLCs, hydraulic and mechanical, motors, CNC machine equipment, spindles, ballscrews and robotics.

Spindles

Our industrial repair services include full-service spindle repairs. We inspect, test and service spindles to restore your CNC machines full capabilities. Once a spindle repair process is complete, it goes through closed loop and run-in testing to ensure optimal balance and the availability for immediate use.

Communications

I/O interface and peripheral control boards may prevent your machine from operating effectively. If not addressed promptly, communication errors can result in material and equipment damage. We work with all brands of CNC systems and restore accurate communications and control of your process.

Robot Systems

Robotics in manufacturing requires a complex balance of mechanical, electrical and hydraulic industrial repair services. A robotic assembly cell may boost your productivity, but a faulty unit may be too complex for your in-house maintenance team to repair in a timely manner. Turn to K+S Services comprehensive robot repair center when your robotics need parts or servicing.

Servo Valves

We offer full-service servo valve repairs for leading manufacturers in all applications. First we pressurize the valve and carefully inspect it for leaks or other faults. Next, we completely disassemble, clean and repair your servo valve before rebuilding it and putting it through rigorous testing.

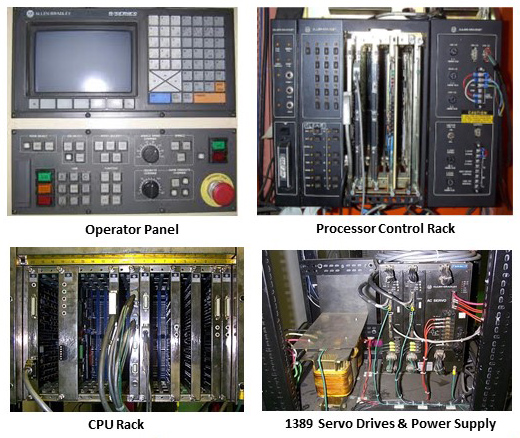

Teach Pendants and Controllers

Teach pendants and PLCs need both hardware and software installation, maintenance and repair services. Turn to K+S Services for turnkey improvements and repairs of your control systems.

Welders

Robot wrists and weld guns can become damaged through malfunction or wear out after routine use. Our industrial machine repair services team has an innovative rebuild and repair program that supports most manufacturers and designs of welding equipment.

Motors

Our industrial motor repair services include full in-house rewinding and rebuilding. Thanks to our impressive inventory of OEM parts, we can easily replace critically damaged components quickly to get you back up and running in no time.

Repairing a motor can create costly downtime in your facility, so work with our team to enjoy rapid repairs and spares without compromising on thorough testing.

Cylinders

A hydraulic cylinder that leaks, grinds or operates slowly can stall your entire process. Choose industrial machine repair services that offer in-house repairs and thorough rebuild services at our state-of-the-art facility.

A large inventory of OEM materials enables us to improve our turnaround time and deliver rebuilt cylinders to meet your deadlines.