Certified Repair Process

K+S’s hydraulic pump repair process integrates industry-leading practices with our ISO 9001 certification standards:

Pump Condition Assessment

We analyze wear patterns, noise issues, and efficiency loss.

Component-Specific Disassembly

Focusing on wear-prone elements like bearings and seals.

Intensive Component Cleaning & Inspection

Checking for cavitation damage and component wear.

OEM-Quality Part Replacement

We only use parts specific to pump models for optimal performance.

Operational Testing under Load

Verifying pressure, flow, and efficiency post-repair.

Pump Failure Analysis Reporting

Detailing causes of wear and potential preventive measures.

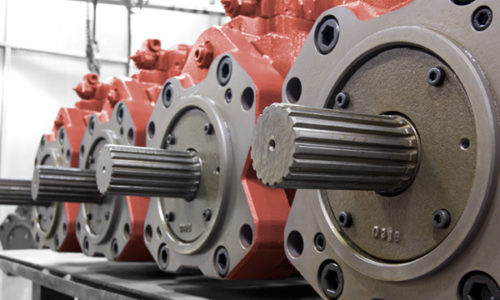

Expert Pump Repair Team

Specialists in diverse hydraulic pump technologies.

High Quality Standards

Upholding ISO 9001 protocols for hydraulic pump repairs.

Brands

K+S services a broad spectrum of hydraulic pump brands, including Denison, Vickers, Bosch Rexroth, and more. Contact us to learn more about the brands we service.

- Denison

- Oilgear

- Racine

- Rexroth

- Vickers

Does My Hydraulic Pump Need Repair?

Consider professional repair if your hydraulic pump shows:

- Reduced pressure or flow.

- Unusual noises or vibrations.

- Heat generation beyond normal levels.

- Contaminated fluid or metallic debris in the oil.

Have further questions about hydraulic pump repair? Contact a K+S expert today to get more information from one of our industrial repair experts.