Certified Repair Process

Our robot wrist repair process at K+S is designed to maximize robotic efficiency and dexterity:

Robotic Motion Analysis

We diagnose issues in wrist articulation, rotation, and grip strength.

Targeted Wrist Component Disassembly

Inspecting joints, gears, and actuation mechanisms.

Focused Cleaning & Examination

Highlighting wear in rotational bearings and electrical connections.

Advanced Robotic Wrist Repair Techniques

Addressing complex mechanical and electronic components.

Precision Testing for Range of Motion

Ensuring smooth and accurate wrist movements.

Robotic Wrist Failure Analysis

We help reduce future repair costs by investigating causes of mechanical degradation or failure.

Robotics Repair Specialists

Technicians with expertise in advanced robotic systems.

ISO 9001 Compliant Repair Process

Ensures that every repair is to the highest industry standard.

Brands

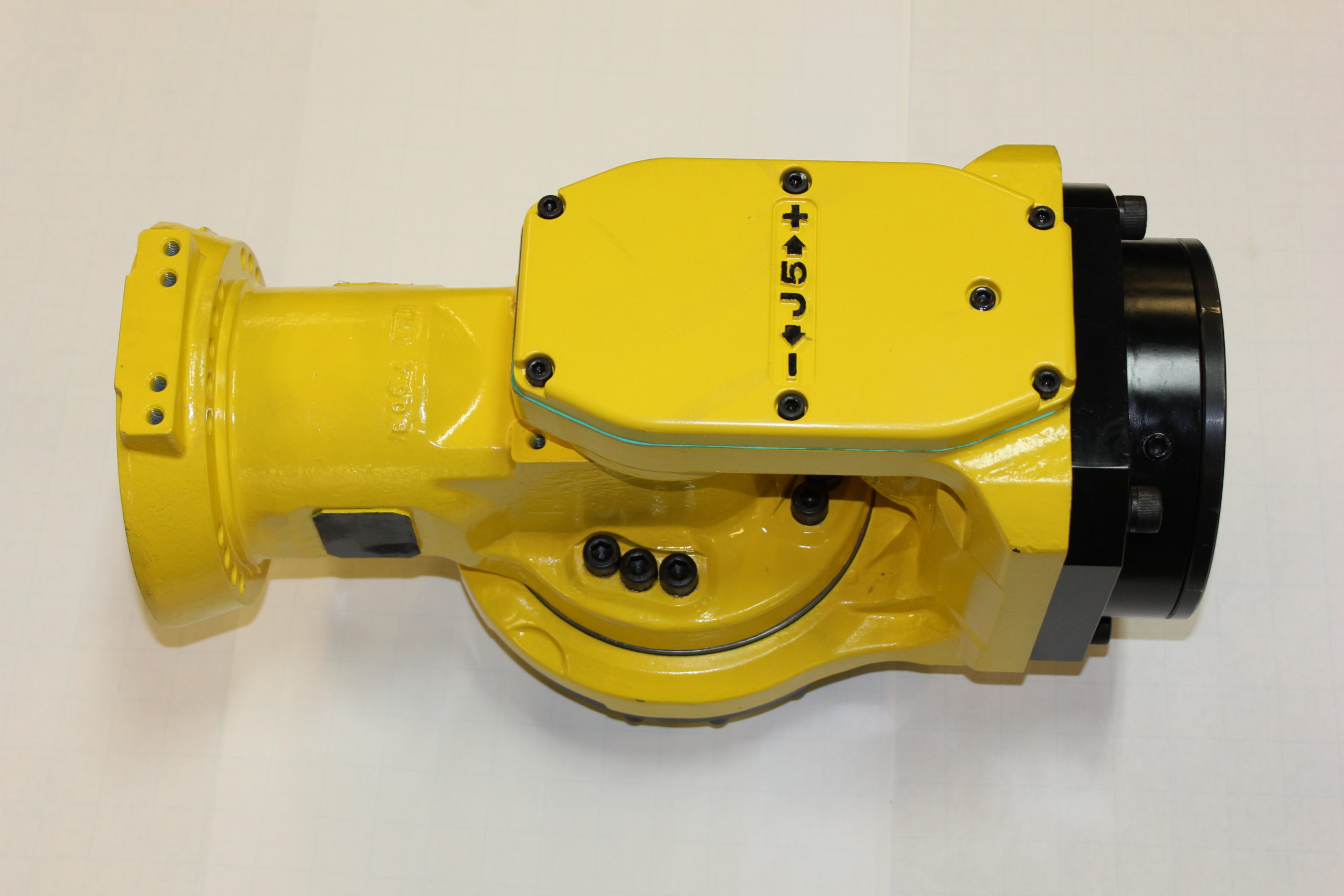

K+S Services is proficient in repairing robot wrists from a wide array of manufacturers, including ABB, Fanuc, Kawasaki, and more.

Does My Robot Wrist Need Repair?

Your robot wrist should be professionally repaired if:

- It exhibits reduced precision or range of motion.

- There are signs of mechanical wear or strain.

- Unusual noises occur during operation.

- Response times are slower or inconsistent.

For more information about when to service robot wrists and other components, contact a K+S industrial repair specialist today.